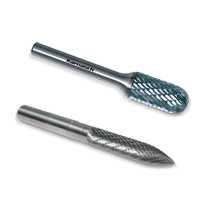

Milling cutters

- Overall Length [mm]: 140

- Drive [mm]: 6

- Quantity: 5

- Condition: New

- Diameter from [mm]: 4

- Diameter up to [mm]: 24

- RPM to [rpm]: 2000

- Number of tools: 1

- Condition: New

- Material: Tool Steel

- Length [mm]: 58

- Weight [g]: 10

- Diameter [mm]: 5

- Condition: New

- Material: High-speed steel

- Surface: Titanium coated

- Diameter [mm]: 8

- Overall Length [mm]: 45

- Effective Length [mm]: 17

- Condition: New

- Diameter [mm]: 8

- Length [mm]: 80

- Material: High-speed steel

- Condition: New

- Diameter [mm]: 9.6

- Length [mm]: 72

- Material: High-speed steel

- Left/Right Cutting: Right cutting

- Weight [g]: 22

- Condition: New

- Diameter [mm]: 8, 9

- Quantity: 2

- Condition: New

- Length [mm]: 70

- Diameter [mm]: 11

- Manufactured in: Germany

- for components see parts list

- Also available as set

- Net weight [kg]: 0,02

- Condition: New

- Number of tools: 6

- for shaft diameter [mm]: 6

- Material: Tool Steel

- Diameter [mm]: 6-15

- RPM to [rpm]: 2000

- Condition: New

- Number of tools: 6

- for shaft diameter [mm]: 6

- Material: Tool Steel

- RPM to [rpm]: 28000

- Condition: New

- Number of tools: 12

- Diameter [mm]: 8

- Surface: Chromed, Satined Matt

- Packaging: Wooden Case

- Condition: New

- Number of tools: 9

- Material: Carbide

- Condition: New

- Number of tools: 15

- for shaft diameter [mm]: 8

- Packaging: Hard shell case

- Suitable For (substance/mix/gas/chemicals): Wood

- Condition: New

- Number of tools: 15

- for shaft diameter [mm]: 6

- Packaging: Hard shell case

- Suitable For (substance/mix/gas/chemicals): Wood

- Condition: New

- Number of tools: 12

- for shaft diameter [mm]: 8

- Packaging: Hard shell case

- Suitable For (substance/mix/gas/chemicals): Wood

- Condition: New

- Number of tools: 12

- for shaft diameter [mm]: 6

- Packaging: Hard shell case

- Suitable For (substance/mix/gas/chemicals): Wood

- Condition: New

- Packaging: Sheet Steel Cassette

- Surface: Blank

- Material: Carbide

- Weight [g]: 590

- Colour: silver

- Number of Parts [parts]: 7

- Condition: New

- Number of tools: 35

- for shaft diameter [mm]: 8

- Material: Silicon carbide

- Packaging: Tool module (PU soft foam inlay), Hard shell case

- Condition: New

- Shape: Conical

- Quantity Unit: Kit

- Quantity: 7

- Shaft diameter [mm]: 6

- Milling Form: Ball Shape, Cylindrical, round

- Condition: New

- Number of tools: 3

- Packaging: Plastic Cassette

- Surface: Blank

- Weight [g]: 100

- Shape: B Shape, D Shape, G Shape

- Length [mm]: 81

- Width [mm]: 69

- Height [mm]: 35

- Quality: Premium

- Weight [kg]: 0,087

- Condition: New

Many kinds of car repair involve milling. It requires special equipment which is fitted with changeable milling cutters - tools with one or several cutting teeth. When being used, these items rotate very quickly and help to make precise cuts, cut threads, make holes, cut-outs, slots and many others.

Types of milling cutters

By the design:

- Solid. Have a solid structure.

- Welded. Their components are made of different materials and are integrated with the help of welding.

- Shell. Their parts are joined together with the help of screws and other fasteners.

By the shape:

- Slitting cutters. Used for cutting a workpiece, fluting, recessing metal, and chamfering.

- Slab cutters. Used to work with three-dimensional workpieces. Often have helical teeth which makes swarf removal easier.

- Face cutters. Allow to effectively work even with the hardest metals, used to work with flat and stepped work-pieces.

- Hob cutters. Widely used in gear cutting, processing of splined shafts and toothed wheels.

- End cutters. Used to process mutually perpendicular planes, make slots, steps and recesses.

In their catalogues, modern companies present products made of various materials. Most often, these are:

- high-speed steel;

- carbon tool steel;

- hard alloys (tungsten-cobalt or titanium-tungsten-cobalt);

- diamond;

- mineral ceramics.

Tools should be chosen depending on the properties of the materials to be processed. For example, ceramic items are often used to cut especially hard and tempered steels, hard-alloy cutters are used to mill soft metals and plastic.

Besides, the intended purpose of a tool defines the way its teeth are sharpened and their shape. For instance, they can be straight, helical or angular.

Milling cutters: tips on use

- Only use the tools that suit the type of the material to be processed and the nature of the task.

- Prior to using the tool, make sure that it is attached properly and has no backlash.

- Wear a respirator while milling.

- Do not use damaged milling cutters. You should replace them if the cutting edges are dull or damaged. Signs of dull teeth can include overheating of the tool, vibration, irregularities on the surface of a workpiece.

- In order to reduce heating of the tools, use cutting fluids. It can be just water or special cooling lubricants that help not only to cool the parts but also to reduce the friction.

Professional help from Buycarparts.co.uk

Would you like to buy milling cutters at affordable prices? Register at Buycarparts.co.uk. In our online shop, you can purchase high-quality tools really inexpensively. Besides, we often hold promotions that help you to save even more. Place an order online on our website right now and appreciate the benefits of advantageous purchases.